Ukugcina ivalve yokuphuma ivaliwe ngexeshaIimpompo ze-Centrifugalumsebenzi wazisa iingozi ezininzi zobugcisa.

Ukuguqulwa kwamandla okungalawulwayo kunye nokungalingani kwe-thermodynamic

- 1.1 Ngaphantsi kwemeko evaliweyo yokunyuka kweqondo lokushisa eliphakathi, phantse onke amandla egalelo aguqulwa abe ngamandla okushisa. I-medium ayikwazi ukukhupha ukushisa, okubangela ukuba ukushisa kwegumbi lokumpompa kunyuke ngokukhawuleza. Ukusebenza ngokuqhubekayo kuya kubangela ukuphunga okuphakathi, ukukhawulezisa i-carbonization yezinto zokutywinwa.

1.2 Ukungaphumeleli kwenkqubo yesitywina Kwimeko yobushushu obuphezulu kunye nomphunga we-medium, itywina lomatshini elixhomekeke kwi-lubrication kunye nokupholisa kwe-medium kuya kukhokelela ekungaphumeleli kwayo kokushisa - i-mechanical seal iya kuba ne-friction eyomileyo kwaye ubuso be-seal buya kutshiswa.

Uxinzelelo olungaqhelekanga lomatshini

- 2.1 I-axial force overrun I-axial force yevalve yokuvala idla ngokuphindwe ka-1.5-5 kwiimeko eziqhelekileyo zokusebenza, kwaye umthwalo othwele i-thrust ungafikelela okanye udlule umda wokuthwala, okukhokelela ekuqhekekeni kwe-cage yokuthwala okanye ukuguqulwa kwekheji.

2.2 Ukutshatyalaliswa kwe-Vibration kunye nomonakalo wokukhathala Umahluko wokwandiswa kwe-thermal obangelwa ukushisa okuphezulu kukhokelela kwi-deformation ye-thermal okanye uxinzelelo lwe-thermal, i-gap engavamile phakathi kwe-impeller kunye ne-pump yezindlu, kunye nefuthe lomthwalo ongenakulinganiswa we-hydraulic, obangela ukuba ulungelelwaniso oluguquguqukayo lwe-rotor lonakaliswe, ukunyuka kwe-vibration, kwaye iindawo zonakaliswe ukukhathala.

I-Cavitation kunye nomonakalo wezinto eziphathekayo

I-3.1 Isibonelelo se-NPSH i-inverted medium vaporization [yenza i-cavitation allowance (NPSHa) yesixhobo esisezantsi kune-NPSHr efunekayo yempompo], ukwenza ama-bubbles, kunye ne-wave shock wave eyenziwa ngokuwa kwe-bubbles inokufikelela kwi-690MPa, okubangelwa ukugoba kunye ne-honeycomb spalling ye-runner impeller.

3.2 Ukuwohloka kwesakhiwo se-metallographic Ukwenzela i-austenitic stainless steel impellers, i-sensitization inokuthi yenzeke kumaqondo okushisa asekuhlaleni, kwaye isantya se-corrosion ye-intergranular iya kwanda kwaye amandla okuqina aya kuncipha. I-carbon steel impellers, iingxaki kwiqondo lokushisa eliphezulu zibaluleke kakhulu, ezifana ne-high-temperature oxidation kunye ne-decarburization, okubangelwa ukuhla kwamandla omhlaba kunye nemigaqo-nkqubo jikelele; Ukuba iqulethe ukungcola okufana ne-sulfure kunye ne-phosphorus, kulula ukuhlula kwimida yengqolowa kumaqondo okushisa aphezulu, okubangela ukutshatyalaliswa kwe-thermal kunye nokuqhekeka lula ngexesha lokusebenza; Ngaphantsi kobushushu obuphezulu bexesha elide, intsimbi yekhabhoni ayinakuxhathiswa kukunyuka, kwaye ubushushu obuphezulu bendawo bunokukhawulezisa i-creep deformation, eya kuthi ekugqibeleni ikhokelele ekuqhekekeni kwe-impeller okanye ukusilela kokudinwa.

Ukhuseleko lwenkqubo kunye nemingcipheko yezoqoqosho

4.1 Uxinzelelo loxinzelelo lweqokobhe elithwele uxinzelelo lidlula umda kwaye ukusebenza kwevalve yokuvala kwenza uxinzelelo lokuphuma kwempompo lufike kwi-120-150% yexabiso elilinganisiweyo, kwaye kukho umngcipheko wokuqhekeka koxinzelelo olubekiweyo lwevalve yokhuseleko, enokubangela ukukhutshwa koxinzelelo loxinzelelo okanye ukuqhekeka kombhobho weld.

4.2 Ukusetyenziswa kwamandla kunye neendleko zokugcinwa kweendleko zokunyuka kweValve yokuvalwa kweValve yi "imeko ebulalayo" yeempompo ze-centrifugal, ezonyusa kakhulu ukusetyenziswa kwamandla kwixesha elifutshane, kunye nokusebenza kwexesha elide kuya kukhokelela kumonakalo onobungozi kwisixhobo, kunye neendleko zokugcinwa kwezixhobo ezibanzi zinokunyuka ngamaxesha angama-3-10.

Ukuwohloka kweemeko zokusebenza kwimidiya ekhethekileyo

Kwimithombo yeendaba eziguquguqukayo (umzekelo, i-LPG), ukusebenza kwevalve evaliweyo kuya kukhawulezisa ukufunxa kwesigaba solwelo, kwaye i-gas-liquid yamanqanaba amabini ukuhamba kwigumbi lokumpompa kuya kubangela utshintsho oluhamba ngokukhawuleza, okukhokelela kwi-oscillations ye-periodic ye-axial forces kunye nokukhawuleza ukunxiba kwamacandelo.

Amava oshishino kunye neemfuno ezisemgangathweni

6.1 Amava oshishinoNgokwawona mava esicelo sobunjineli, umda wexesha lokusebenza wevalve yempompo ye-centrifugal awuyi kuba ngaphezu kwemizuzu emi-2, kwaye udla ngokulinganiselwa kumzuzu omnye. Kunconywa ukuseta inkqubo yokulawula ukuvala i-interlock ukuqalisa ngokuzenzekelayo inkqubo yokukhusela ukuvala xa ivalve yokuphuma ivala kunye namaxesha angaphezulu.

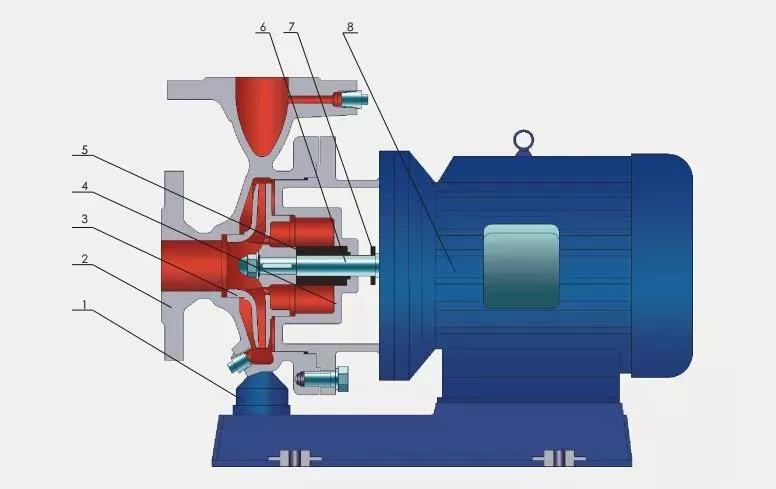

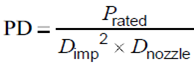

I-6.2 Ukuchazwa okusemgangathweni kufuna ukuba umgangatho we-API 610 we-12th Edition uthi ezinye iipompo eziphezulu zamandla, ezidibeneyo okanye ze-multistage zinokunyuka kweqondo lokushisa ngokukhawuleza xa i-valve yokuphuma ivaliwe, eyenza uvavanyo lungenakwenzeka kunye / okanye lungakhuselekanga xa i-valve ivaliwe. Ukunyuka kwamaqondo obushushu kusondelelene nokuxinana kwamandla. Uxinaniso lwamandla PD, olunokuqikelelwa ngolu hlobo:

Ireyithingi yombane kwinqanaba ngalinye xa amanzi e-hp (okanye MW)

D imp: Ilinganiswe ngedayamitha ye-impeller kwi-. (okanye m)

D nozzle: Nominal outlet flange idayamitha ngaphakathi. (okanye m). Ukufunxa kabini, iimpompo zenqanaba elinye, umbhobho we-D yidayamitha yeflange yokungena.

Ixabiso elibalulekileyo eliqhelekileyo le-PD yi-0.286 hp / in.3 (13 MW / m3), ngaphaya koko kucetyiswa ukuba ungaqhubeki umpompo kunye ne-valve yokuphuma ivaliwe ngexesha lokuvavanya ukusebenza.

Ixesha lokuposa: Jun-04-2025

sales@tkflow.com

sales@tkflow.com